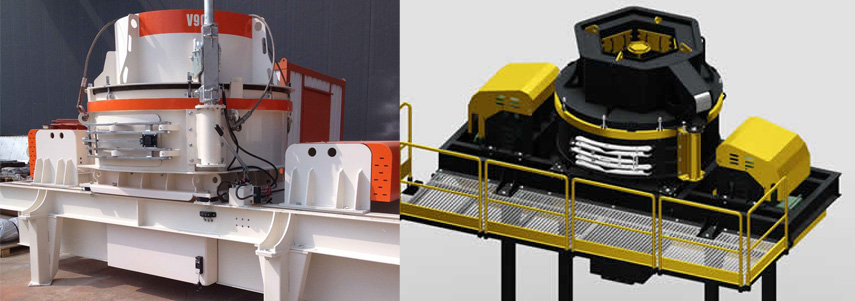

The type of crusher, which is one of the indispensable parts of the construction industry and involved in the crushing process, is the vertical shaft crusher. Vertical shaft crusher is the crushing of medium-sized abrasive and hard materials found in mines and stream beds and extracted from construction sites with the help of a crusher and minimizing the flour. Vertical shaft crushers, which are required in all construction site projects, are used to obtain sand, gravel and gravel from stones. The maintenance of these construction machines, whose installation is very simple, can also be done easily. These products, which are generally used for breaking medium-sized stones and mines, also have a serious success in breaking small materials. Wet, moist and sticky materials are also designed in a structure that allows them to be thinned in the vertical shaft crusher to the dimensions requested by the user.

In the crusher plant, known as the stone crushing and screening plant, assistance is taken from the vertical shaft crusher to obtain sand from the aggregate, which is the basic raw material of the building and construction industry. There are many machinery and equipment in the crusher plants for the realization of the projects. Auxiliary crushers in obtaining sand are only one of these machines. Vertical shaft crushers, which perform the crushing process by rotating at high speed thanks to the equipment called rotor, follow a successful path to breaking the abrasive and high hardness stones, as well as the breaking of the stones that are in contact with water or that are moist. Vertical shaft crushers, which allow any type of stone to be crushed and brought to the desired and desired size, have very important advantages for companies or businesses.

Working Principle of Vertical Shaft Crushers with Di-Çelik

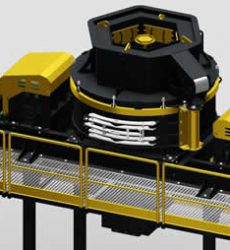

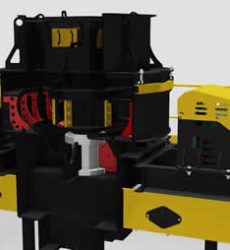

Vertical shaft crushers, which enable efficient crushing of almost every type of stone and ore, even with high abrasiveness, start to work with high rotational movement. Rather than breaking the precious metals or stones extracted in mines, stream beds and all other construction projects by crashing within the mechanism of the machine; These construction machines, which interact with other stones and allow them to crash into each other, perform their operations with the principle of transforming the kinetic energy in the materials into crushing and impact energy.

The material to be crushed falls into the mechanism with a rapid rotor movement from the feeding chute of the machine and the stones that gain kinetic energy are transmitted to the crushing section. Materials that gain kinetic energy thanks to the rotor power; In the crushing section, the kinetic energy is converted into impact energy as a result of the stones colliding with each other and the materials are provided to reach the desired dimensions.

Benefits of Vertical Shaft Crushers to Companies

All equipment and machines produced in Di-Çelik facilities and to be used in crusher facilities are designed and manufactured according to the needs and demands of the companies. For this reason, each machine produced is unique and contains the features that will benefit the business. Vertical shaft crushers located in crusher plants and under the title of spindle crushers also offer significant advantages to the company or its user, like all other machines. Vertical shaft crushers produced in Di-Çelik facilities;

- Bringing substances to the required cubicity

- An efficient performance in the crushing process of materials found in stream beds and mines,

- Easy assembly and disassembly of the machine,

- Bringing high abrasive and hard materials to the desired size easily

- It provides advantages such as the ability to process moist or wet materials regardless of their structure, and enables them to obtain high profits at low costs.

Di-Çelik Vertical Shaft Crusher Features

These crushers, which are manufactured to be used in abrasive material crushing with Di-Çelik, take charge in the crusher plants as the third crusher. The fineness ratios of all produced materials are small and cubical.

Turbo crushers have a closed type rotor, and there are rock chambers around the rotor that help break hard and highly abrasive stones. In the crushing of materials with low abrasiveness and a soft structure, the armor ring can be attached to the machine as an accessory. All adjustments can be made by changing the gradation rotor speed.

In the Di-Çelik facility, which has different types of vertical shaft impact crushers, the machines operating with a capacity power of 50 tons to 90 tons per hour, and the types that make crushing operations between 250 and 400 tons per hour are also available in our facility. Vertical shaft crusher feed sizes have options in the range of 28 mm, 38 mm, 45 mm and 80 mm. Vertical shaft crushers, which have different weight options from 7500 kilograms to 19,000 kilograms, operate from 185 kW to 2 x 250-315 kW engine power. Rotor diameters vary for each machine type, but vary between 700 mm and 1200 mm.

You can contact Di-Çelik, which has the opportunity to do business with almost any company operating in the construction and building sectors, and get information about our working policy that supports 100% customer satisfaction.

| Model | VSI-700 | VSI-800 | VSI-900 | VSI-1000 OPEN ROTOR | VSI-1200 OPEN ROTOR |

| Rotor Diameter | 700(mm) | 900(mm) | 900(mm) | 1000(mm) | 1200(mm) |

| Feed Size | 28 (mm) | 38 (mm) | 45 (mm) | 80 (mm) | 80 (mm) |

| Capacity | 50-90 (ton) | 60-150 (ton) | 100-150 (ton) | 150-300 (ton) | 200-400 (ton) |

| Motor Power | 132-160 kW | 2x160-200 kW | 2x200-250 kW | 2x200-250 kW | 2x315-355 kW |

| Weight | 7500 (kg) | 11500 (kg) | 14000 (kg) | 14500 (kg) | 19000 (kg) |