Sand Washing and Screening Plants

Sand is an important substance that is frequently used in all areas of our lives, especially in the construction industry. Sand is among the products used primarily in the construction phase of the houses we live in and all the buildings around us. It is a very important detail that the sand should be of good quality, as are all the materials used for the construction to be strong and durable. Sand, which has been sifted, washed and passed through all stages professionally, is always more preferred in the construction and building sector. While sand is natural and pure, it cannot be used in road construction and similar areas because it may contain foreign matter, while its processed and sifted form can be easily used in all buildings and constructions that come to mind.

What are the Advantages of Sand Screening?

Since sand is a main material used in every construction, it should be used by purifying it from harmful and natural residues. This is a method that should be done in order not to encounter some problems in the area where sand will be used in the future and to prevent waste and residues in nature from appearing in construction. Only in this way, bad appearance and situations that threaten building security are prevented. Thus, higher quality materials are used. The sands used in almost every area differ according to the area of use. The content of the sand used in road construction and the sand used in plastering are different from each other. Depending on the condition of the structure, the sand should be sifted more finely and purified in detail.

Why is a Sand Washing and Screening Plant Needed?

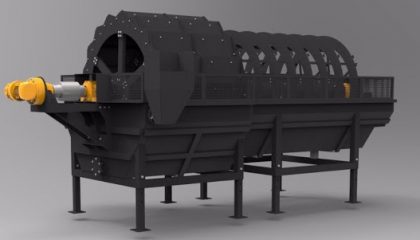

The sand washing and screening process takes place in a capacity facility within the scope of experts in the field. The equipment in our facility is extremely safe and high quality equipment. Equipment produced using state-of-the-art tools offers ease of use and professionalism in the work done. There is also a large-volume sieving machine in our sieving facility, which enables easy operation with its automatic electrical and control cabinet. Sand separating machine with spiral bladed bucket, fine sand collection conveyor, aggregate hopper, dosage band, feeding conveyor between hopper and sieving machine are other equipments in our facility. As Di-Çelik, we offer the best service in our sand washing and screening facility.

How Do We Do the Washing and Screening Process?

The purpose of sifting the sand is to be purified from all foreign materials and put it into use in its best form. Our di steel machinery company, which performs this process in the best way, starts the washing and screening process of the sand brought from the seaside or the area such as sand quarry where the sand is located. Materials such as stones and gravel in the sifted sand are separated from each other with the help of mixers and separators. In addition to the sieving method, the sand washing process in our facility is also carried out with bucket sand separation machine and bucket washer. The sand, which decomposes at the end of all these processes and has a clean appearance, is sold to be used in the construction sector and all areas where it is needed. As Di-Çelik, we carry out all these stages in a perfect and practical way.